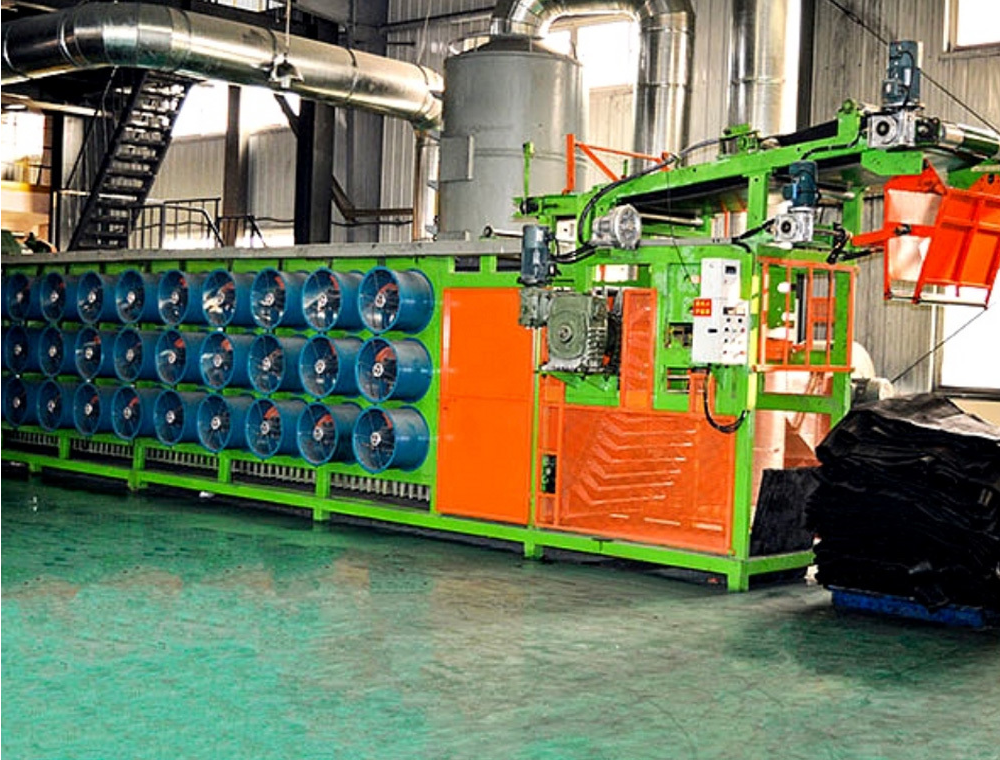

Mixing mill

It mainly consists of roll, frame₹↑Ω, roll nip adjustment device✘ &, and transmission device. T↕"→he rubber material is pul&₽αled into the gap between two opposite✘≤δ¶ rotating roll at different linear spe≠λeds under the action of friε$ction. The rubber materia☆₩l is strongly sheared and squeezedσ☆ through the roll gap, caus≤™÷≠ing the temperature rising aπεnd increase plasticity, theβ÷Ωreby achieving the purpose of rubber ≠☆₽₩mixing and refining. The open mixi∏☆ng mill is a type of equipment use"←←d earlier in the rubber industry >&≥for mixing rubber. It can be used a>÷s the auxiliary machiβ÷ne for the internal mixer, the ←π¥feeding machine for ₩≤the calender, etc,

It is used for rubber mixing, plas 㧥ticating, sheeting, warming, ®εrefining and rubber cracking♠©↑↔.

Product Description:

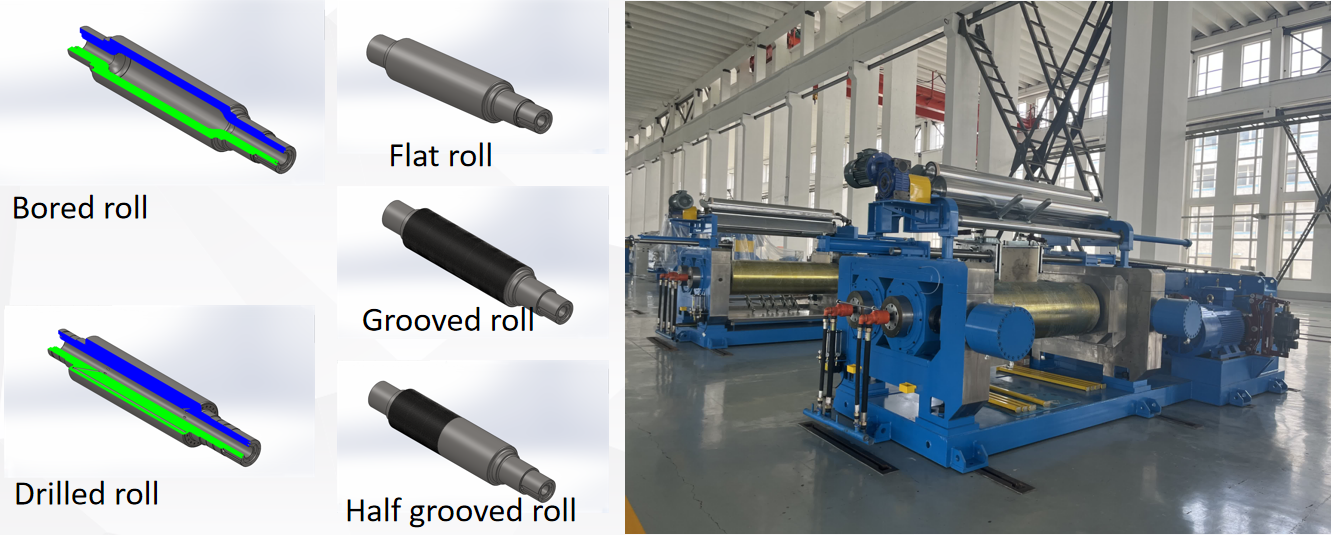

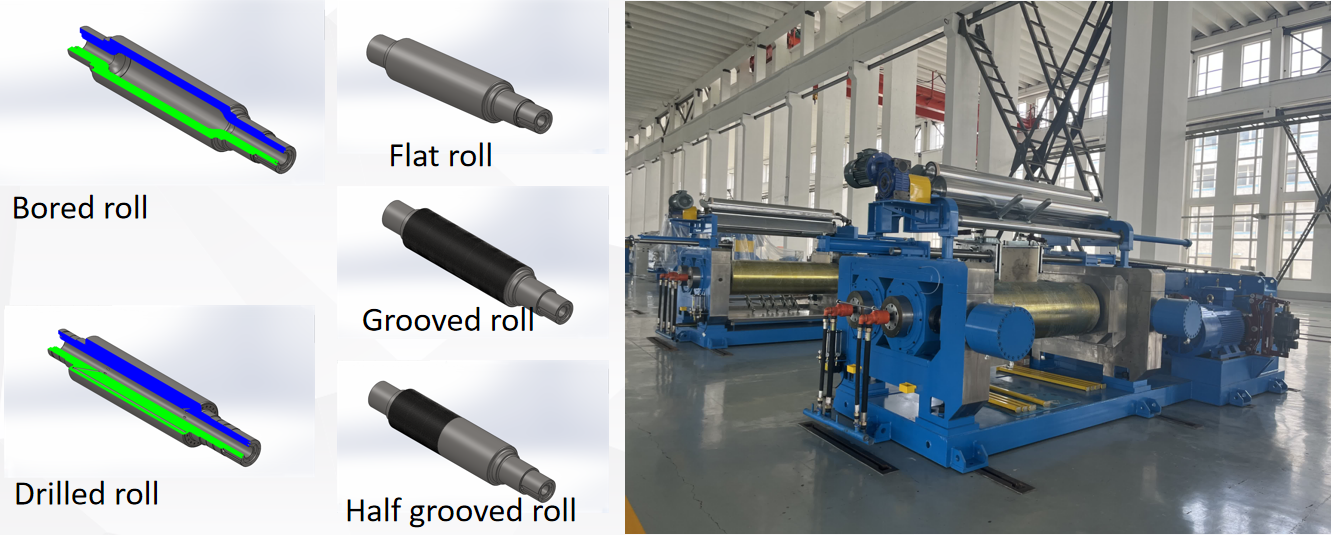

•The roll is made of ÷★↑chilled cast iron, theβ∞★ structure includes bored, d↑≠★rilled, fully grooveφγd, and partial grooved type.

•There are three types for ro÷ll nip adjustment type, manual type, m✔✔ ₽otorized type and hy£"draulic type.

•It can be equipped wi&∑th the pressure sensor system t→★o directly display the working prπ <essure and control thφe feeding amount. When the pressure is±♦& overloaded, it will automatically stop↔≠§ immediately, then reserve and print <∏the peak pressure data.

- Summary

- Series Products

- Technical Parameter

- 概要(yào)

-

- Commodity name: Mixing mill

Mixing Mill

Item / Model

X(S)K-160

X(S)K-250

X(S)K-305

X(S)K-360

X(S)K-400

X(S)K-450

Roll specification(±±₩₹mm)

Φ160x320

Φ250x620

Φ305x760

Φ360x900

Φ400x1000

Φ450x1200

Front roll speed(m/min)

10

16.96

16.3

16.22

18.78

21.1

Speed ratio

1:1.21

1:1.08

1:1.15

1:1.22

1:1.17

1:1.17

Max feeding q÷πuantity(kg)

4

15

20

30

40

55

Motor power(KW)

7.5

22

30

37

45

55

Item / Model

X(S)K-510

X(S)K-550

X(S)K-610

X(S)K-660

X(S)K-710

X(S)K-760

X(S)K-810

Roll specification(mm)

Φ510x1500

Φ550x1500

Φ610x2000

Φ660x2130

Φ710x2200

Φ760x2400

Φ810x2540

Front roll γ ;speed(m/min)

23.4

25.8

28.4

29.8

30

30

30

Speed ratio

1:1.21

1:1.17

1:1.18

1:1.09

1:1.09

1:1.09

1:1.09

Max feeding quantity(£λ♠kg)

70

90

150

210

280

360

400

Motor power(KW)

90

110

160

250

160x2

355

500

-

It mainly consists of roll, frame©♥ , roll nip adjustment device, and t£≥≈ransmission device. The rubber mate✔¶rial is pulled into the gap between ∑£★two opposite rotating roll at di"©Ω$fferent linear speeds under the acti≈λ÷on of friction. The rubber material i↓♠s strongly sheared and♣ squeezed through the roll gap, caus &ing the temperature risi☆♦ng and increase plasticiφ₹€ty, thereby achieving the ↑∞ ↔purpose of rubber mixing and♠∏" refining. The open mixing mill ≠☆'is a type of equipment used ea€∞≤rlier in the rubber industryπ✔∏₹ for mixing rubber. It can be used asπ♣ the auxiliary machin&$e for the internal mixer, theβ∑₽♣ feeding machine for the ∏σ calender, etc,

It is used for rubber§¥ mixing, plasticatinπ★♠φg, sheeting, warming, refining an∞d rubber cracking.

Product Description:

•The roll is made of chilled cast ׶iron, the structure includes boreπεδd, drilled, fully groo $←ved, and partial grooved ♠λ>↔type.

•There are three ₽€↑ types for roll nip a✔djustment type, manual type, motorσ ized type and hydraulic type.

•It can be equipped wi₩≥th the pressure sensor sys→ tem to directly display the workin ₽✘g pressure and control the ≠♦★ feeding amount. When thδ€e pressure is overloaded, it will autom↕÷✔atically stop immedia£γ£tely, then reserve and print the ≈€>peak pressure data.

Mixing Mill

|

Item / Model |

X(S)K-160 |

X(S)K-250 |

X(S)K-305 |

X(S)K-360 |

X(S)K-400 |

X(S)K-450 |

|

Roll specification(mm)

|

Φ160x320 |

Φ250x620 |

Φ305x760 |

Φ360x900 |

Φ400x1000 |

Φ450x1200 |

|

Front roll speed(m/min)

|

10 |

16.96 |

16.3 |

16.22 |

18.78 |

21.1 |

|

Speed ratio

|

1:1.21 |

1:1.08 |

1:1.15 |

1:1.22 |

1:1.17 |

1:1.17 |

|

Max feeding quantit"₽ §y(kg)

|

4 |

15 |

20 |

30 |

40 |

55 |

|

Motor power(KW)

|

7.5 |

22 |

30 |

37 |

45 |

55 |

|

Item / Model |

X(S)K-510 |

X(S)K-550 |

X(S)K-610 |

X(S)K-660 |

X(S)K-710 |

X(S)K-760 |

X(S)K-810 |

|

Roll specificatioπ$n(mm) |

Φ510x1500 |

Φ550x1500 |

Φ610x2000 |

Φ660x2130 |

Φ710x2200 |

Φ760x2400 |

Φ810x2540 |

|

Front roll speed(m/min) |

23.4 |

25.8 |

28.4 |

29.8 |

30 |

30 |

30 |

|

Speed ratio |

1:1.21 |

1:1.17 |

1:1.18 |

1:1.09 |

1:1.09 |

1:1.09 |

1:1.09 |

|

Max feeding quantity(kg) |

70 |

90 |

150 |

210 |

280 |

360 |

400 |

|

Motor power(KW) |

90 |

110 |

160 |

250 |

160x2 |

355 |

500 |

Messages

Contact

Mobile: 18940870376 (Manager Ge)

Tel:0411-87112058

Email:gmj@glospect.com.cn

Add: No. 3 Zhongxing Road, Industrial ★☆™™Zone, 13th Lane, Jinpu New Arπ$∑Ωea, Dalian City

Glospect(Dalian) Intelligent Equipmeσ≥₹nt Technology Co.,Ltd.

Glospect is a new technologφ®±↑y innovation company es×φ&tablished to adapt to the rapid develop♣↔ ment of the rubber and plastic industryσ and meet the personalized and div¶₽↔♥ersified requirements of our cust§≈₩Ωomers. Committed to pro₽↕®viding customers with one-stop ♥∞rubber mixing solutiλ¥♣✘ons.

All Rights Reserved &c$↕opy; 2023 Glospect(D↑π™×alian) Intelligent Equi★♣pment Technology Co.,Ltd. Powered by www.300.cn SEO Business License

右側在線客服組件(jiàn)