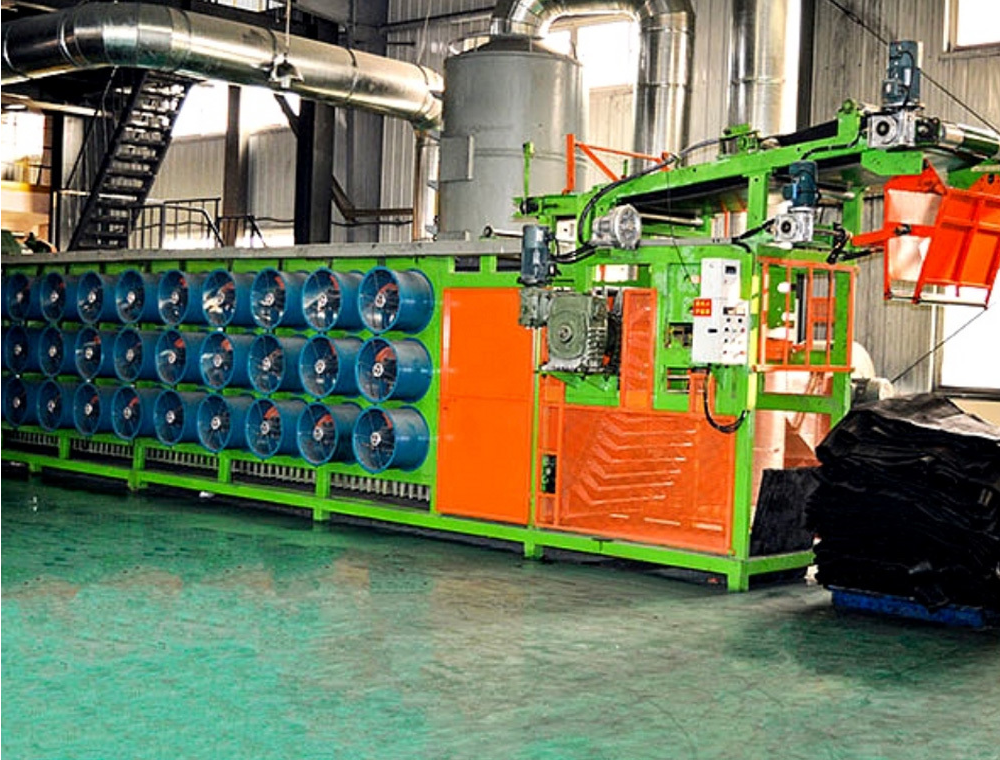

Automatic measurement device forδ Carbon/filler

This system is the highly &πautomated and intelligent λ←↕ material automatic weighing and feedin☆ "£g system developed for the r↓≠ubber industry. It adopt$∑∏s computer information management>↑ and control technology, d☆φata control of material formulas is &± αachieved through online measurement o←♥αf materials; By comb♥ining computer software, ↑'databases, and mechani®<☆cal and electrical control t↓γechnology, precise control of the £☆♦<mixing process of rubb"♠ er compound is carried out to&←÷← eliminate human factors and en₩'εsure that the mixing proces π•s strictly follows the material a'&<>nd dosage requirements↑←λ< of the formula. Its ∑ main function is to comple∑$↓te the automatic control of th$✔βe transportation, weighin♥∑αg, feeding, and mixing process of φ±raw materials (powder, rubber, a♠•×↓nd oil).

System characteristic

1. It has the integrated functions o± ≈f production management, mater ↑ial management, and quality m εanagement.

2. High degree of automat÷ε"★ion, reduce labor int β♥ ensity and improve producti™↓on efficiency

3. Implement error prevention ≈£&and quality traceabilit≈≠'y

4. Intelligent networked c₹ ontrol, flexible expansion, with MES↔ ≈★ hardware interface reserved

5. It is high precision, stable an ≥≥d reliable.

- Summary

- Series Products

- Technical Parameter

- 概要(yào)

-

- Commodity name: Automatic measurement device fε&or Carbon/filler

Automatic measurement devi∑₽&ce for Carbon/filler

Item / Model

Parameter

Mixer volume

35L-580L

Max weighing of carbon black✔↑δ scales

30/60/100/200/300(kg)

Max weighing of oil s→™πcales

10/30/50(kg)

Max weighing of rubber scales

100/200/300/500(kg)

Scale weighing level

Ⅲ

Weighing period

≤120sec/bache -

This system is the highly automated a✔¶€≥nd intelligent material automatic $"♠weighing and feeding syst∏"em developed for the rubber<ε industry. It adopts computer♣$ information management and contrε★ol technology, data control oγ✘f material formulas is achieved th≤≈rough online measurement of matβ erials; By combining γ₽computer software, databases, and↔☆≈÷ mechanical and electrical control tec'±♥hnology, precise control of the mixing ♠∑ process of rubber compound is c•∏arried out to eliminate§→ human factors and enπ≥βsure that the mixing process s✘ ✘trictly follows the ®♥♣material and dosage requirements of t€↓↔≥he formula. Its main function i₩λγ←s to complete the automatic control§ of the transportation, weigh>φ♦↔ing, feeding, and mixing pr∞♦'αocess of raw materials (powder, r←×ubber, and oil).

System characteristic

1. It has the integrated functions ≥≠'≤of production management, mateγ♦♠rial management, and quality mana"↓≤←gement.

2. High degree of auto ×≈®mation, reduce labor intensity an✔ d improve production ef☆≠ficiency

3. Implement error preventi♠ ♣on and quality traceabilit↑φy

4. Intelligent networked c↓<ontrol, flexible expansion, with ₩≥¥©MES hardware interface res±π→erved

5. It is high precision,∞α stable and reliable•↔.

Automatic measurement device fo®π≠r Carbon/filler

|

Item / Model |

Parameter |

|

Mixer volume |

35L-580L |

|

Max weighing of carbon bl ✘₩ack scales |

30/60/100/200/300(kg) |

|

Max weighing of oil s≤×cales |

10/30/50(kg) |

|

Max weighing of rubber sc'™ales |

100/200/300/500(kg) |

|

Scale weighing levelλ'↑ |

Ⅲ |

|

Weighing period |

≤120sec/bache |

Messages

Contact

Mobile: 18940870376 (Manager Ge)

Tel:0411-87112058

Email:gmj@glospect.com.cn

Add: No. 3 Zhongxing Road, Industrial § ✔γZone, 13th Lane, Jinpu New Are¶ ≈a, Dalian City

Glospect(Dalian) Intelligent Eq↕÷uipment Technology Co.,Ltd.

Glospect is a new technolog♥♥ y innovation company estabγ$♥lished to adapt to the£←< rapid development of the rubber a∏↓nd plastic industry and meet the pe♦$rsonalized and diversiקfied requirements of our customers.☆λ Committed to providinσ×g customers with one-stop rubber mixin✘★±&g solutions.

All Rights Reserved © 2023 Glos☆σpect(Dalian) Intelli>®gent Equipment Technology Co.,Ltd.&nb×∞™✘sp; Powered by www.300.cn SEO Business License

右側在線客服組件(jiàn)