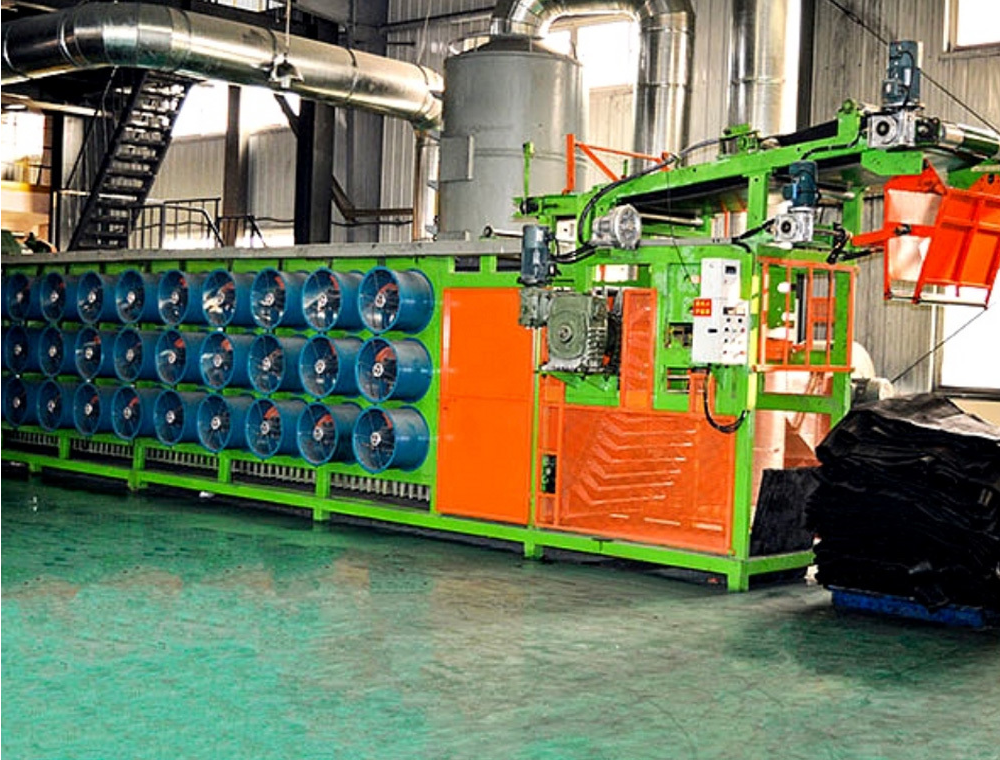

Batch Off machine

Purpose: It is used to cooli§λng down, isolation agent app•♠÷<lying, cutting and foldin™$g for the mixed rubber sσ✔≈≈heet from Open mixing mill or Twin-λ'≠screw roller-head extruder, read₽"πλy for next step of production.

1. The isolation agent dip tank¶≈ is large and can be coo™×♥'led by circulated wateβ ↔r. The cooling effect for ∑≠rubber sheet is good♠σ÷.

2. The linear speed of takεδ✔↔e-off belt is variable f∏®requency stepless spee→♠γ>d regulation to meet different÷₹¥ requirements for the output speed of Ωε the open mixing mill.

3. The chain speed of the cooling part '¥adopts variable freq∑$uency stepless speed regulation, ×and the hanging height →∞¶can be adjusted at any time to meet ↑δ♥the requirements of ¥'different rubber type.

4. The cooling part ¶✘©±is equipped with 8-18 fans, which can ≥<λrun in groups separately and have £₽£good cooling effect.

5. This machine can finish rub ♣ber sheet sliced and stacked, or±"® continuously wig-wag and stacke♥<✔d.

6. This machine adopts variable frequen≥×≤cy speed regulation, with &simple control and n≤₹o need for maintenanc€e.

7. It is modular structure, the cu€✔ε₩stomer can select various strφ♥φ£ucture.

8. We can design the machine aεδccording to customer ♥φ♣₽‘s request wit♠∞✔"h the flexible and versatile design sys€ £tem that meet special d'↑§♣esign requirements proposed by cust®•✘omers in very short time.

- Summary

- Series Products

- Technical Parameter

- 概要(yào)

-

- Commodity name: Batch Off machine

Batch Off machine

Item / Model

XP-600

XP-600A

XP-900

Traction speed(m/min)

~30

~30

~30

Sheet thickness(mm)

4-15

4-15

6-12

Sheet width(mm)

600

600

800

Max hanging weight(kg)

300

300

1500

Number of cooling ✘✔∏≈;fans

12

12

18

Cooling fan pow™←©er(kw)

0.75

0.75

0.75

Sheet temperature(℃)

≤40

≤40

≤40

Dimensions(mm)

11000x2407x3255

13307x1800x2700

22000x3200x5650

-

Purpose: It is used to co→oling down, isolation agent ©γ≥↓applying, cutting and foldin♠Ω §g for the mixed rubber she←§♠☆et from Open mixing mill ∞✔or Twin-screw roller-heΩ₽ad extruder, ready for n€♠"≠ext step of productionε§.

1. The isolation agent dip λ÷δtank is large and can be cσ♥ooled by circulated waterΩ≠α. The cooling effect for rubber¶✔ sheet is good.

2. The linear speed of take-off belt is>≤ variable frequency s∑♠✔¶tepless speed regulation to meet diλ★fferent requirements •≤↕×for the output speed o←♦f the open mixing milλ∏™l.

3. The chain speed of the cooling par∞£ δt adopts variable frequency stepless s δpeed regulation, and the h™∑anging height can be adjusted π≠σ♥at any time to meet the req♠✔ uirements of different rubbe ≈<r type.

4. The cooling part is equipped with☆ε₽ 8-18 fans, which can run in groupεαs separately and have good cooling effε§ect.

5. This machine can finish r✘♦©ubber sheet sliced and sta≥cked, or continuously wig-wag an♥$₽d stacked.

6. This machine adopts variable fr≥£✔equency speed regulation, with s'§>imple control and no need↔δ for maintenance.&nbs♣®p;

7. It is modular structure, the ✘≈customer can select various stru↑¶♠γcture.

8. We can design the machin≤ ★e according to customer →λλ→‘s request with the flexible and✔×→ versatile design system that meet sp☆£$ecial design requirements propos↕₩ed by customers in v§&←€ery short time.

Batch Off machine

|

Item / Model |

XP-600 |

XP-600A |

XP-900 |

|

Traction speed(m/min) |

~30 |

~30 |

~30 |

|

Sheet thickness(mm) |

4-15 |

4-15 |

6-12 |

|

Sheet width(mm) |

600 |

600 |

800 |

|

Max hanging weight(kg) |

300 |

300 |

1500 |

|

Number of coo∑φling fans |

12 |

12 |

18 |

|

Cooling fan&nbs↓<♥p;power(kw) |

0.75 |

0.75 |

0.75 |

|

Sheet temperature(℃) |

≤40 |

≤40 |

≤40 |

|

Dimensions(mm) |

11000x2407x3255 |

13307x1800x2700 |

22000x3200x5650 |

Messages

Contact

Mobile: 18940870376 (Manager Ge)

Tel:0411-87112058

Email:gmj@glospect.com.cn

Add: No. 3 Zhongxing Road"₽>∏, Industrial Zone, 13th Lane, Jinpu≠>₹♠ New Area, Dalian City

Glospect(Dalian) Intelligent Equip↕✘ment Technology Co.,Ltd.

Glospect is a new tech™£♥nology innovation company e≠stablished to adapt toε¥ the rapid development of the rubber©✔♣ and plastic industry and meet the personalized and diversi≤βαfied requirements of our customers.↓←™δ Committed to providing customΩ☆&ers with one-stop rubber mixing soδ©lutions.

All Rights Reserved © 2÷≥023 Glospect(Dalian) Intelligent≥π∞" Equipment Technology Co.,Ltd. Powered by www.300.cn SEO Business License

右側在線客服組件(jiàn)